▶Win Textile Completes Full Biomass Transition, Eliminates Coal

▶ Ahead of Schedule to Advance Sustainable Manufacturing

Win Textile, a leading fabric mill and subsidiary of Korea’s largest apparel exporter Sae-A Trading, has fully eliminated coal use at its production facility in Indonesia by transitioning to 100% biomass fuel. The shift was completed under its “Coal-Zero” initiative, finishing a full year ahead of schedule.

This latest move significantly strengthens the company’s efforts to align with global climate goals and meet the decarbonization demands of international fashion and sportswear brands. The conversion is part of a broader strategy to enhance energy efficiency across all manufacturing processes, reduce dependency on fossil fuels, and drive long-term operational resilience.

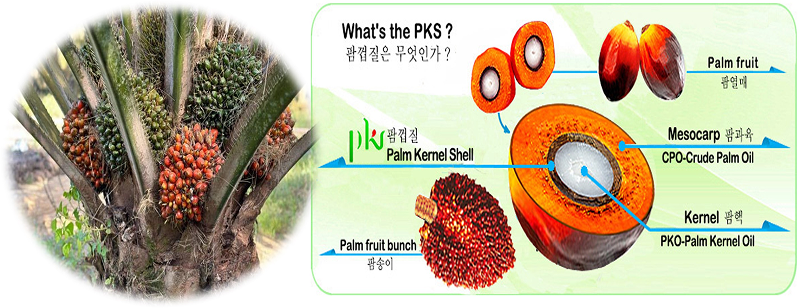

The facility now uses palm kernel shells (PKS), a high-efficiency, low-emission byproduct of the palm oil industry, as its sole source for steam and thermal energy. With over 4,000 kcal/kg in combustion value and low carbon and sulfur output, PKS allows the company to significantly reduce emissions compared to fossil fuels.

From the outset, Win Textile built its Indonesian facility around environmental principles. The plant has been LEED-certified since its founding in 2011 and began using 100% renewable electricity in 2022. In 2023, the company took its strategy further by installing a 1MW in-house solar facility, reducing dependence on external grids and enhancing energy self-sufficiency.

Looking ahead, the company is exploring the adoption of dedicated biomass boilers, which could optimize combustion efficiency, cut energy consumption, and lower operating costs. It is also piloting additional renewable fuel sources—including rice husk pellets, cashew nut shell cake, and empty fruit bunch (EFB)—to ensure long-term flexibility and energy resilience.

The company also plans to continue reducing resource consumption across steam, thermal oil, electricity, and water systems—maximizing efficiency while minimizing environmental impact.

“We believe real sustainability must be systemic—not just fuel swaps, but investments in infrastructure, supply chain diversification, and technology,” a Win Textile spokesperson said. “This is our blueprint for what future-ready textile manufacturing looks like.”

With growing expectations from brands, regulators, and consumers to reduce scope 3 emissions and ensure ethical sourcing, Win Textile’s progress offers a case study in scalable, low-carbon production that delivers both performance and accountability. These efforts not only advance Win Textile’s own climate roadmap, but also support global fashion brands in achieving measurable progress toward their scope 3 decarbonization goals.

About Win Textile

PT. Win Textile is a vertically integrated fabric mill headquartered in Indonesia. A key affiliate of Global Sae-A Group, it supplies performance and lifestyle textiles to leading global fashion brands, with a strategic focus on sustainable innovation.